Create Time: 08 ,12 ,2025

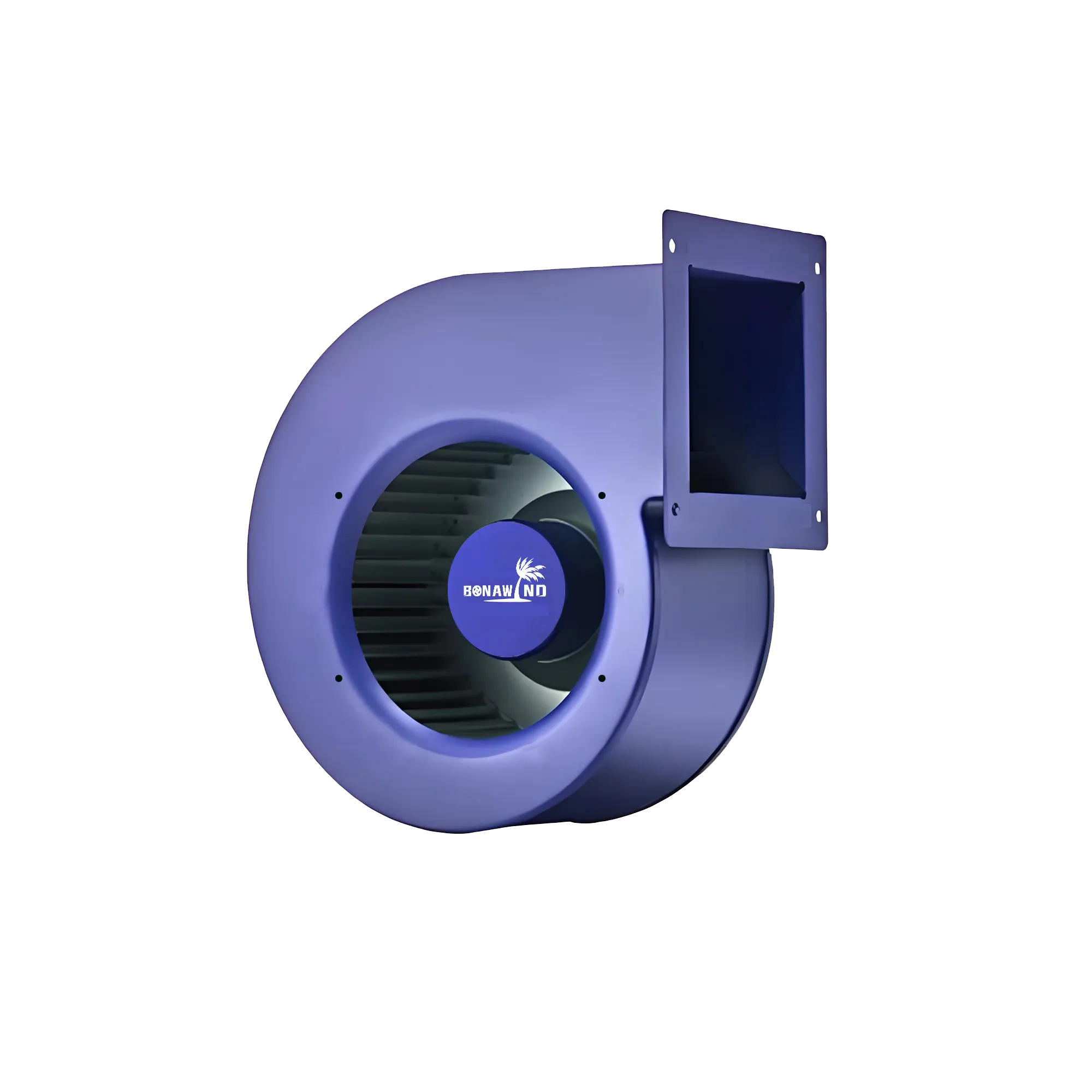

In large industrial facilities, agricultural barns, or warehouses, proper ventilation is critical for maintaining air quality, controlling temperature, and ensuring the comfort of both workers and animals. One of the most effective solutions for this is the 48 inch industrial exhaust fan. With its large blade diameter, durable build, and high airflow capacity, this fan is a popular choice across many industries. But how exactly does it improve airflow and efficiency?

Understanding the Role of a 48 Inch Exhaust Fan

A 48 inch exhaust fan is designed to move a significant volume of air in a short amount of time. Compared to smaller models, its wide blade span allows for greater air displacement, making it ideal for ventilating large areas. In environments such as poultry farms, factories, or greenhouses, removing hot, stale air and replacing it with fresh air is crucial for both productivity and safety.

Industrial facilities with heat-producing machinery often face excessive indoor temperatures. Without adequate ventilation, heat stress can impact worker performance, equipment efficiency, and product quality. Installing a 48 inch louvered exhaust fan helps solve this by continuously expelling hot air and drawing in cooler outside air.

Why Choose a Louvered Exhaust Fan for Industrial Use?

A 48 inch louvered exhaust fan comes with built-in shutters that automatically open when the fan operates and close when it stops. This design helps:

Prevent dust and debris from entering the facility.

Block rainwater during storms.

Reduce energy loss by keeping the space sealed when the fan is not in use.

This makes them particularly valuable for agricultural applications. For example, in poultry farms, pairing a poultry cooling fan with an industrial exhaust fan ensures consistent airflow, reducing ammonia buildup and heat stress among livestock.

Applications of the 48 x 48 Exhaust Fan

The 48 x 48 exhaust fan can be used in:

Poultry farms – keeping livestock cool and improving air quality.

Warehouses – removing hot air and reducing reliance on air conditioning.

Industrial workshops – providing fresh air to meet safety standards.

Greenhouses – regulating temperature and humidity for plant growth.

For large open spaces, pairing the fan with industrial ceiling fan suppliers’ HVLS (High Volume Low Speed) fans can improve airflow even further.

Energy Efficiency and Cost Savings

While high airflow fans consume electricity, they can significantly reduce cooling costs. By exhausting hot air efficiently, you can lower the demand on HVAC systems. Additionally, modern industrial exhaust fan ceiling models are designed to operate with optimal energy efficiency, using motors that consume less power while maintaining strong airflow.

A 48 inch industrial exhaust fan is a valuable investment for anyone managing large spaces where air quality and temperature control are priorities. Whether you operate a factory, warehouse, or poultry facility, the right ventilation system can improve working conditions, protect equipment, and even save on energy costs.

English

English  中文

中文  日本語

日本語  français

français  Deutsch

Deutsch  Español

Español  русский

русский  português

português  العربية

العربية